Choosing Fuel Line Fittings for Project Cars

When building or upgrading a project vehicle, selecting the right fuel line fittings and classic car fuel pipe fittings is a crucial step that affects both performance and safety. Modifying fuel lines often involves custom routing, various sizes, and different standards. For enthusiasts working on fuel system projects, knowing how to choose the appropriate fittings for your specific build can help prevent leaks, simplify installation, and ensure long-term reliability.

1. Start with a Clear Fuel Line Plan

Before acquiring fuel line fittings, map out your project car’s fuel routing. Many builders, when building custom lines, discover routing challenges — such as running lines near steering racks or heat sources — that influence the types of fittings and hose style they choose.

Consider where the fuel pump, filter, and engine bay connections are relative to the chassis and steering components.

Avoid routing fuel lines directly under components that may transfer heat or cause abrasion during motion.

Plan for bends, supports, and clearances so you know whether angled fittings or straight fittings work best.

Good planning makes selecting the right auto fuel line fittings easier and increases reliability once installed.

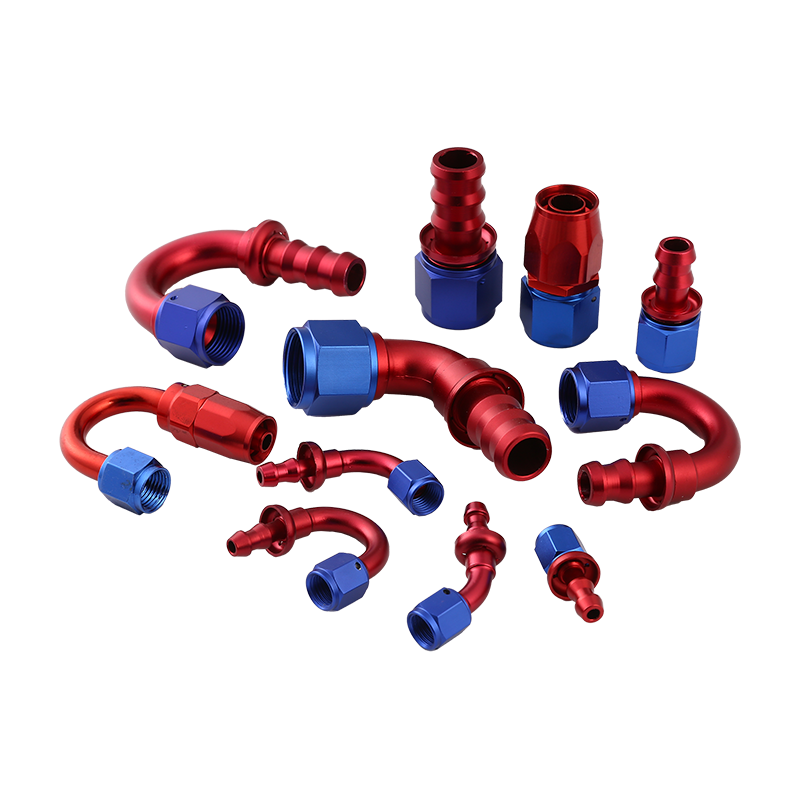

2. Choose Fittings That Match Your Hose and Pressure Requirements

Project cars often use aftermarket hoses — such as stainless braided PTFE — to handle pressure and routing flexibility. However, these lines require fittings designed for that specific hose type: standard rubber hoses use different fittings compared to braided lines.

AN fittings are common for custom builds and provide secure connections with performance hoses.

Quick-disconnect fittings may be tempting for convenience, but many builders find traditional AN fittings are safer and less prone to issues.

If you are adapting old hard lines (e.g., from a vintage chassis) to new hose, you’ll often need adapters or specific compression fittings.

Match your fittings to hose inner diameter (ID), outer diameter (OD), and expected fuel pressure for a secure, dependable setup.

3. Understand Adapter and Transition Needs

When integrating aftermarket fuel line systems into existing chassis hardlines, adapters are often necessary. Users working on custom fuel lines commonly ask about how to connect factory hard line fittings to aftermarket hoses or adapters like AN--type fittings.

For example:

Some Corvette builders discuss converting an OEM M16x1.5 male fitting to an AN-6 setup using adapters and compression fittings.

Classic car owners sometimes route new lines through existing hardline mounts with carefully chosen adapters for correct fit.

Adapter planning prevents mismatches during assembly and reduces the chance of leaks.

4. Prioritize Safety Over Shortcuts

Fuel system safety should be your top priority. In project car threads, users warn against “quick fixes” such as using barbed fittings on pressurized systems unless they’re rated for fuel injection pressures.

Barbed fittings and clamps might work temporarily, but they are generally seen as less safe than proper compression or AN fittings.

Always ensure fuel line components are rated for the type of fuel and pressure system (carbureted vs EFI).

Use ferrules, O-rings, and seals where appropriate to maintain leak-free performance.

By prioritizing components designed for your application, you reduce the risk of fuel leaks and fire hazards.

5. Material Selection Matters

The material of both lines and fittings affects longevity and performance:

Stainless steel or corrosion-resistant metal fittings and lines help prevent rust and deterioration over time.

PTFE-lined hoses with braided covers resist heat and vibration better than basic rubber hoses in many project car contexts.

Linhai Alway Technology Co., Ltd. offers a range of fuel line fittings made from materials suitable for both daily drivers and custom builds, helping reduce common problems like corrosion and fitting failures in challenging environments.

6. Test Fit Before Final Assembly

One common piece of advice across project car forums is to test fit all components before fueling the system. Dry fitting helps confirm that:

All adapters and fittings align without stress.

Hose routing avoids sharp bends or pinch points.

Connection types are compatible and secure.

Testing allows you to adjust before permanent assembly, saving time and preventing unsafe setups.

English

English

Español

Español

.png)

.png)