Rising Demand Drives Fuel Quick Connector Innovations

In the advancing automotive supply industry, automotive fuel pipe fittings and car fuel pipe connectors have become essential elements of modern vehicle fuel systems. Now that stricter emissions regulations and consumer demand for reliability are growing, innovation around fuel quick connector systems is accelerating rapidly.

1. Why Innovation in Fuel Quick Connectors Matters

1.1 Enhanced Efficiency in Fuel Line Assembly

Fuel quick connectors simplify installation by offering push‑in coupling designs—this reduces assembly time and lowers the risk of leak points. As fuel system complexity increases, car fuel pipe connectors are evolving to support safer, more efficient connections for fuel delivery and return lines. Innovation targets installation speed and long-term sealing integrity.

1.2 Responding to Regulatory Pressure and Operating Conditions

Automotive systems must now endure higher pressures, temperature harshs, and volatile environments—all while maintaining good fuel delivery. Modern automotive fuel pipe fittings incorporate materials like reinforced nylon, stainless steel alloys, and composite plastics to meet these demands while resisting corrosion and wear.

2. Technological Trends Driving Growth

2.1 AI-Assisted R&D and Predictive Design

The industry is increasingly leveraging AI and automation to accelerate innovation in fuel quick connector development. Machine learning models help simulate material behavior under stress, enabling faster design cycles and improved durability predictions. These digital workflows help shorten iteration times and lower development costs.

2.2 Self-Sealing and Automated Valve Features

Next‑generation connectors now include self‑sealing valves that automatically shut off when disconnected, preventing leaks during maintenance or service. Some designs even incorporate one-way shut-off actuators and integrated pressure regulators, increasing safety and ease of use.

2.3 Smart Sensor–Integrated Connectors

Here we are going to see the emergence of smart fuel connectors with embedded sensors. These components can monitor flow, pressure, or temperature in real time. The idea is to detect early signs of pressure drops or leaks, enabling predictive maintenance and real-time diagnostics.

3. Market Trends and Growth Outlook

3.1 Expanding Market Size

The global market for fuel line connectors is projected to grow from roughly USD 5 billion in 2024 to over USD 8 billion by the early 2030s at a compounded growth rate exceeding 6 percent annually. Rising demand in passenger vehicles, commercial heavy-duty systems, and hybrid cars drives this expansion.

3.2 Regional Dynamics

Demand in Asia-Pacific is particularly strong, boosting production of both standard and high-pressure car fuel pipe connectors. North America and Europe are also investing in technological upgrades due to regulatory standards and emission targets.

4. Design Breakthroughs and Material Innovations

4.1 Composite and Reinforced Polymers

To reduce weight and improve corrosion resistance, manufacturers are shifting toward composite plastics and reinforced polymers in fuel quick connectors. These materials help lower production costs while delivering improved mechanical performance under variable pressures.

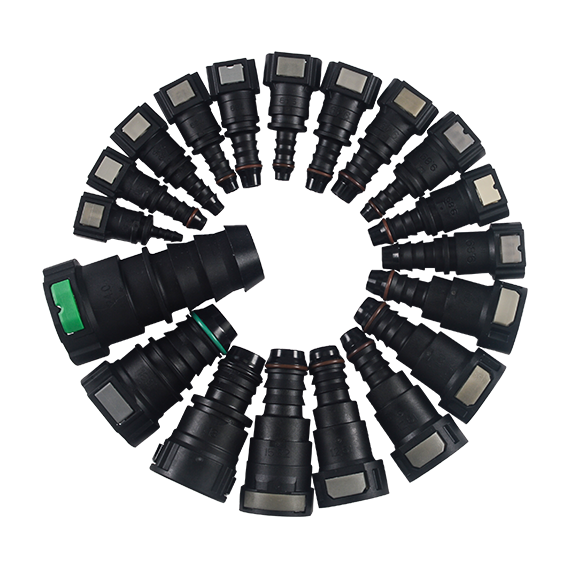

4.2 Color-Coded and Ergonomic Design

Some connectors now use color coding or keyed designs to minimize mis‑installation risk. Ergonomically shaped release mechanisms support one‑handed operation in tight engine bays, improving assembly speed and worker safety.

5. Applications and Use Cases

Internal‑combustion engine vehicles: standard applications of automotive fuel pipe fittings.

Hybrid/electric vehicles: using connectors for auxiliary fuel systems or vapor recovery.

Commercial platforms: trucks, buses, large-engine systems that benefit from service-friendly quick connectors.

Aftermarket upgrades: performance fueling systems using high‑flow connectors and custom assemblies.

To learn more about designing or sourcing advanced fuel connector assemblies tailored to your applications, feel free to reach out.

English

English

Español

Español

.png)