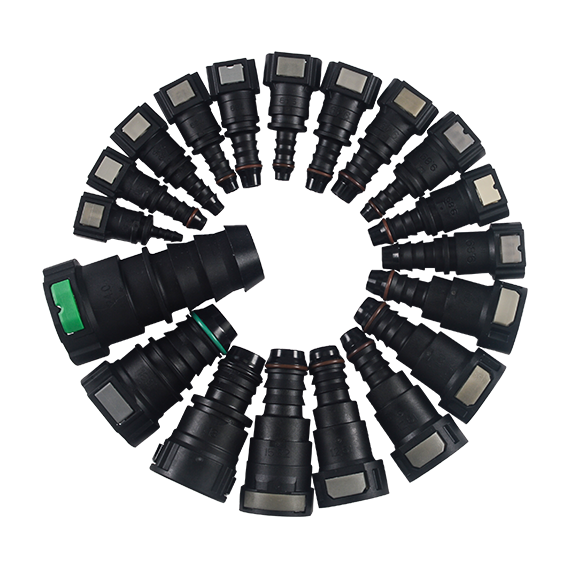

New Materials Enhancing Car Fuel Pipe Connector Durability

As vehicle engine systems become more advanced, so do the demands placed on fuel delivery components. Automotive fuel pipe fittings and car fuel pipe connectors are no longer simple plastic couplings—they are precision-engineered parts designed to endure high pressures, vibration, and chemical exposure. With that in mind, new materials are playing a major role in extending the life and performance of fuel pipe connectors.

1. Understanding Durability in Automotive Fuel Systems

1.1 Operating Environment Challenges

Fuel pipe connectors must withstand constant exposure to gasoline, diesel, ethanol blends, and temperature conditions ranging from sub-zero winters to engine bay heat. Vibration, pressure fluctuations, and chemical corrosion all contribute to potential wear. That’s why choosing the right material is critical in car fuel pipe connector design.

1.2 Lifespan Expectations in Modern Vehicles

Many OEMs now expect automotive fuel pipe fittings to last the entire lifespan of the vehicle—often more than 10 years or 150,000+ kilometers. This pushes manufacturers to explore next-generation materials that are both lightweight and exceptionally resistant to fatigue, warping, or leakage over time.

2. Material Advancements Transforming Fuel Connector Design

2.1 Reinforced Nylon (PA66-GF)

One of the more common upgrades in recent years is the adoption of glass fiber–reinforced nylon. This material offers:

High tensile strength

reliable chemical resistance

Dimensional stability under heat

Low moisture absorption

Because reinforced nylon resists warping and cracking, it’s ideal for complex shapes and thin-walled connectors used in tight engine layouts.

2.2 Stainless Steel and Metal Inserts

For fuel connectors used in high-pressure systems—especially in direct injection or diesel vehicles—stainless steel is often added to the structure. Some designs feature:

Metal core inserts to improve strength

Corrosion-proof stainless shells for longevity

Hybrid metal-polymer constructions for thermal resistance

The combination of plastic flexibility and metal strength allows for precision-sealing without excess weight.

3. Emerging Composite and Hybrid Materials

3.1 Thermoplastic Composites

Recent developments in thermoplastic composites have introduced connectors that weigh up to 30% less than conventional designs, with equal or better mechanical properties. These materials are:

Easier to recycle

Moldable into complex shapes

Ideal for multi-port connectors or integrated valves

Some fuel connectors now also feature multi-layer barrier coatings to resist fuel permeation—important for meeting global emission standards.

3.2 Carbon Fiber Reinforcement

For performance or heavy-duty vehicles, carbon fiber reinforced plastic (CFRP) is an emerging option. Though more expensive, these materials provide:

better heat resistance

harsh durability under vibration

Lightweight design that reduces total vehicle mass

This is especially useful in motorsport or hybrid-electric vehicle applications.

4. How Material Choices Affect Connector Assembly and Performance

4.1 Snap-Fit and Sealing Accuracy

New materials are not only stronger—they’re also more precise. For example, improved moldability of reinforced nylon results in better snap-fit performance, tighter tolerances, and more reliable sealing between fuel pipe ends.

4.2 Resistance to Fuel Type Degradation

With the growing use of ethanol and biofuels, older materials like standard PA6 or PVC can degrade quickly. Modern fuel connectors are tested for resistance to:

E10, E20, or E85 fuel blends

Diesel and biodiesel mixtures

VOC exposure from vapor lines

Upgrading to higher-grade materials ensures connectors don’t soften, swell, or crack under chemical exposure.

5. The Role of Testing and Quality Standards

Material performance is only meaningful if it stands up to rigorous testing. Today’s automotive fuel pipe fittings are subject to:

Pressure cycling and burst testing

Vibration simulation under heat

Salt spray corrosion tests

Fuel immersion for chemical aging

Connectors made from reinforced or composite materials consistently outperform traditional plastics in these tests, proving their long-term reliability.

By continuing to adopt advanced materials and stay aligned with global standards, manufacturers can offer customers more reliable, adaptable, and future-ready fuel connector solutions.

English

English

Español

Español