How Advanced Materials Improve Fuel Connector Performance

The automotive industry continues to evolve with innovations in materials science, pilot to more efficient and durable components. Among these critical parts, Car Fuel Pipe Connectors and Fuel Quick Connectors play a vital role in ensuring safe and efficient fuel delivery. Advances in material technology have significantly enhanced their performance, offering better durability, chemical resistance, and reliability.

The Importance of High-Performance Fuel Connectors

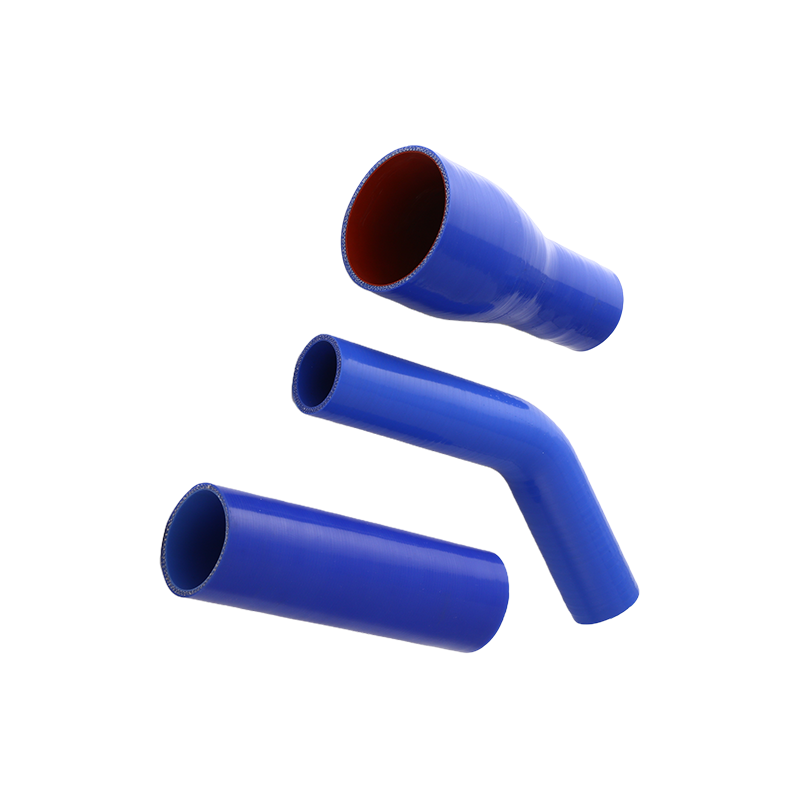

Car Fuel Pipe Connectors and Fuel Quick Connectors are essential for maintaining a secure and leak-free fuel system. Traditional materials like basic plastics or low-grade metals often struggled with corrosion, wear, and chemical degradation over time. However, advanced polymers and composite materials now provide advanced resistance to harsh conditions, including exposure to ethanol-blended fuels, hard temperatures, and mechanical stress.

Key Material Advancements in Fuel Connectors

1. High-Temperature Resistant Polymers

Modern Fuel Quick Connectors often utilize specialized thermoplastics such as PPS (Polyphenylene Sulfide) or PEEK (Polyether Ether Ketone). These materials withstand high under-hood temperatures without deforming, ensuring a consistent seal. Unlike older plastics that could become brittle or warp, these advanced polymers maintain structural integrity even in demanding environments.

2. Chemical-Resistant Composites

Ethanol and other fuel additives can degrade conventional materials, pilot to leaks or failures. Newer Car Fuel Pipe Connectors incorporate chemically inert composites that resist swelling, cracking, and erosion. This ensures long-term compatibility with modern fuel formulations, reducing maintenance needs and improving safety.

3. Reinforced Nylon and Fiberglass Blends

For added strength, many Fuel Quick Connectors now use reinforced nylon or fiberglass-infused polymers. These materials offer nice tensile strength while remaining lightweight, making them ideal for high-pressure fuel systems. Their enhanced durability less the risk of cracks or fractures under vibration and mechanical load.

4. Corrosion-Resistant Metal Alloys

While polymers dominate many connector designs, some Car Fuel Pipe Connectors still require metal components for structural support. Advanced stainless steel and aluminum alloys with protective coatings prevent rust and oxidation, extending service life even in humid or salty environments.

5. Flexible Yet Durable Elastomers

Seals and gaskets within Fuel Quick Connectors benefit from advanced elastomers like FKM (Fluorocarbon Rubber) or HNBR (Hydrogenated Nitrile Butadiene Rubber). These materials maintain flexibility in cold temperatures while resisting fuel permeation, ensuring a reliable seal over time.

Benefits of Upgraded Materials in Fuel Connectors

The shift to advanced materials provides several key advantages:

Longer Lifespan – Resistant to wear, chemicals, and heat, modern connectors last significantly longer than older versions.

Improved Safety – Reduced risk of leaks or ruptures enhances overall fuel system reliability.

Better Fuel Efficiency – A secure connection prevents vapor loss and ensures good fuel delivery.

Easier Maintenance – Durable materials reduce the frequency of replacements and repairs.

Environmental Resistance – Performs reliably in hard weather, from freezing winters to scorching summers.

Future Trends in Fuel Connector Materials

Research continues into even more advanced solutions, such as:

Self-Healing Polymers – Materials that can repair minor cracks or abrasions autonomously.

Nanocomposites – Enhanced strength and chemical resistance through nanoparticle integration.

Bio-Based Plastics – Sustainable alternatives that maintain performance while reducing environmental impact.

These innovations will further optimize Car Fuel Pipe Connectors and Fuel Quick Connectors, meeting stricter emissions regulations and evolving automotive designs.

By understanding these material improvements, manufacturers and consumers alike can make informed decisions when selecting or maintaining fuel system components. Investing in high-quality connectors made from advanced materials ensures better vehicle performance, safety, and longevity.

English

English

Español

Español

.png)

.png)