Fuel Line Fittings Leak Prevention Tips

When working on your vehicle’s fuel system, addressing auto fuel line fittings properly is crucial to prevent dangerous fuel leaks and ensure reliable performance. Fuel line fittings are the connection points that join sections of fuel hose and fuel pipe together, and failure at these junctions is one of the more common causes of fuel leakage.

1. Understand Why Fuel Line Leak Prevention Matters

Fuel leaks are not only wasteful but can present serious safety hazards. A leaking fuel line fitting can reduce fuel efficiency, create fire risks, and cause engine performance issues. Ensuring that auto fuel line fittings and classic car fuel pipe fittings are installed correctly and maintained regularly will significantly lower the risk of leaks and improve the longevity of your fuel delivery system.

2. Choose the Right Fuel Fittings for Your Application

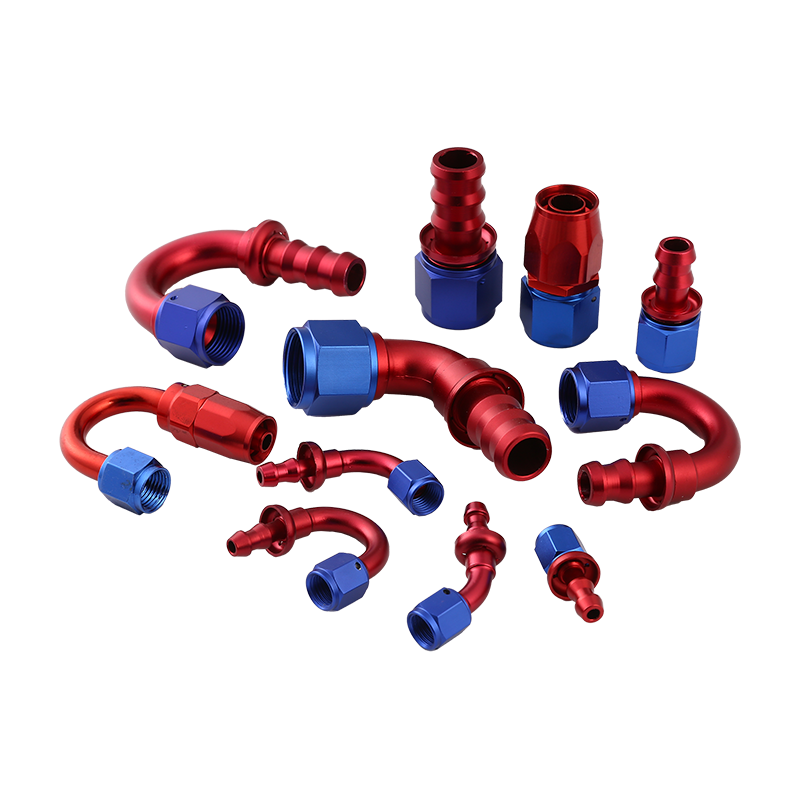

Selecting the correct type of fitting and material is the initial line of defense against leaks. Fuel fittings come in many forms—flare fittings, compression fittings, barbed fittings, and more. Each has its specific advantages and ideal use contexts:

Flare fittings create a metal-to-metal seal and are widely used for rigid fuel pipes because they resist vibration and high pressure.

Barbed fittings are common with flexible rubber fuel hoses, using hose clamps to secure the connection.

Compression fittings are sometimes used, but they may be more prone to leaks if not installed precisely.

When selecting fittings, make sure they are compatible with the type of fuel, pressures, and temperatures your system will see. Linhai Alway Technology Co., Ltd. recommends always verifying fitting specs against your vehicle’s requirements for safety and performance.

3. Inspect Fuel Lines and Fittings Regularly

Prevention starts with routine checks. Over time, fuel line fittings may degrade due to corrosion, vibration, and heat cycles. Inspect the connections periodically:

Look for signs of cracks, rust, or looseness. A cracked fitting or loose nut often indicates an impending leak.

Pay extra attention to older vehicles or classic cars, where original pipe fittings may have aged or weathered significantly.

Check rubber hoses for brittleness or swelling, especially when connected to metal fittings that might cut or stress the hose.

Regular visual inspection helps you catch problems before they turn into fuel leaks.

4. Use Proper Installation Techniques

Correct installation is as important as choosing the right parts:

Tighten fittings to proper specifications. Over-tightening can damage the fitting or hose, resulting in leaks, while under-tightening won’t secure the seal effectively.

For flare fittings, make sure the flare angle and surface are clean and matched to the fitting to ensure a proper seal.

If you are not experienced, consider having installation carried out by a trained technician or get expert guidance from your supplier.

When installed correctly, quality fuel fittings will provide a secure, leak-resistant connection that holds up under pressure.

5. Consider Environment and Operating Conditions

Fittings must withstand the environment in which they operate:

Fuel systems generate heat, and fittings are exposed to extended temperature cycles. Materials like corrosion-resistant metals and quality polymers perform better under such stress.

Vehicles exposed to moisture, salt, or rough conditions may experience faster corrosion, making frequent inspection and high-quality materials essential.

Choosing the right materials for auto fuel line fittings and classic car fuel pipe fittings based on your operating environment reduces future maintenance issues.

6. Repair or Replace Faulty Components Promptly

When you identify a potential leak:

Don’t delay repairs. Even a small seep can widen over time.

Replace old or worn fittings with correctly rated replacements. Linhai Alway Technology Co., Ltd. offers a variety of fuel line fitting options designed for durability and resistance to corrosion and wear.

When in doubt, have a professional fuel system inspection to ensure all connections meet safety standards.

Prompt action not only prevents leaks but also helps maintain steady fuel pressure and reliable engine performance.

Leak prevention for auto fuel line fittings is not just about tightening a nut—it involves selecting the right components, installing them correctly, inspecting them regularly, and responding quickly to wear. By following these preventative tips, you can safeguard your vehicle’s fuel system, improve efficiency, and reduce the risk of dangerous fuel leaks. Regular maintenance and attention to detail are key to a long-lasting and safe fuel delivery system.

English

English

Español

Español