The Role Of Quality Control In Radiator Hose Manufacturers' Operations

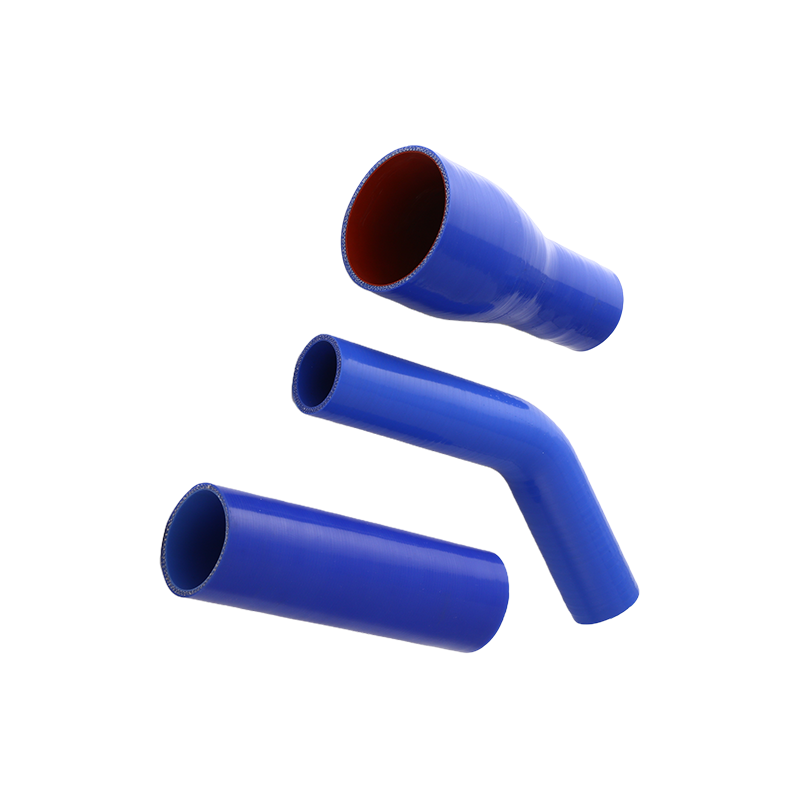

ODM Custom Radiator Coolant Hose Manufacturers Manufacturing

Quality control is a crucial aspect of operations for radiator hose manufacturers. It ensures that products meet the stringent standards required for performance and safety in automotive applications. For radiator hose manufacturers, the implementation of rigorous quality control measures is essential to maintain reliability and customer satisfaction.

Radiator hose manufacturers must adhere to strict quality control protocols throughout the production process. This begins with the selection of raw materials. High-quality materials are fundamental to producing durable and reliable radiator hoses. Radiator hose manufacturers perform extensive testing of raw materials to ensure they meet industry standards. By controlling the quality of these materials, manufacturers can prevent defects that could compromise the performance of the final product.

During the manufacturing process, radiator hose manufacturers employ various quality control techniques to monitor and maintain product integrity. One key method is regular inspection of production equipment. Radiator hose manufacturers must ensure that machinery is properly calibrated and maintained to avoid deviations in hose dimensions and performance. Regular maintenance checks and calibration procedures help radiator hose manufacturers achieve consistent product quality.

In addition to equipment inspections, radiator hose manufacturers conduct frequent quality checks on the hoses themselves. This includes testing for factors such as pressure resistance, flexibility, and durability. Radiator hose manufacturers use specialized testing equipment to simulate real-world conditions, ensuring that each hose performs effectively under stress. These tests are crucial for identifying any potential weaknesses in the hoses and addressing them before the product reaches the market.

Another important aspect of quality control for radiator hose manufacturers is the implementation of standardized procedures and protocols. Radiator hose manufacturers develop detailed quality control plans that outline specific steps and criteria for each stage of production. These plans include guidelines for material handling, processing techniques, and final inspections. By following these standardized procedures, radiator hose manufacturers can maintain a high level of consistency and reliability in their products.

Training and development of personnel are also vital components of quality control for radiator hose manufacturers. Skilled operators and quality control inspectors play a significant role in maintaining product standards. Radiator hose manufacturers invest in ongoing training programs to ensure that their staff is knowledgeable about the new quality control techniques and industry developments. This commitment to staff development helps radiator hose manufacturers uphold high-quality standards and adapt to evolving industry requirements.

Customer feedback is another valuable resource for radiator hose manufacturers in their quality control efforts. By analyzing feedback and addressing concerns raised by customers, radiator hose manufacturers can identify areas for improvement and implement necessary changes. This proactive approach helps radiator hose manufacturers enhance their products and address any quality issues that may arise.

Radiator hose manufacturers also leverage advanced technologies to improve their quality control processes. Automation and data analytics are increasingly being used to monitor production and detect potential issues. Radiator hose manufacturers utilize these technologies to gather real-time data, analyze trends, and make informed decisions about quality control measures. This technology-driven approach enables radiator hose manufacturers to enhance accuracy and efficiency in their quality control efforts.

In summary, quality control plays a vital role in the operations of radiator hose manufacturers. From the selection of raw materials to the final inspection of finished products, radiator hose manufacturers must implement rigorous quality control measures to ensure that their hoses meet industry standards. By focusing on material quality, equipment maintenance, standardized procedures, staff training, customer feedback, and advanced technologies, radiator hose manufacturers can maintain high standards and deliver reliable products to their customers. The commitment to quality control is essential for radiator hose manufacturers to remain competitive and meet the demands of the automotive industry.

English

English

Español

Español

.png)

.png)