The Role Of Custom Coolant Hose In Improving Equipment Performance

Supply ODM Custom Fuel Hose For Coolant Exporter Producer

Custom coolant hoses play a crucial role in improving equipment performance across various industries. These specialized hoses are designed to transport coolant fluids efficiently, ensuring that machinery and equipment operate at good temperatures. By understanding the significance of custom coolant hoses, we can appreciate their impact on equipment longevity and efficiency.

Custom coolant hoses are tailored to meet the specific requirements of different machines and systems. Unlike standard hoses, which may not fit ideally or withstand operational conditions, custom coolant hoses are manufactured to precise specifications. This customization ensures that the hoses can handle the specific pressures, temperatures, and chemical interactions they will encounter in their application.

One of the primary advantages of using custom coolant hoses is the prevention of overheating. Overheating is a common issue that can ideal to significant equipment damage and downtime. Custom coolant hoses are designed to provide efficient and consistent coolant flow, which helps maintain the ideal operating temperature of the equipment. This temperature regulation is essential for preventing thermal stress and prolonging the lifespan of the machinery.

In addition to temperature regulation, custom coolant hoses also contribute to improved equipment performance by reducing the risk of leaks and failures. Standard hoses may not always fit ideally, pilot to potential leaks that can compromise the cooling system. Custom coolant hoses, on the other hand, are designed to fit precisely, less the chances of leaks and ensuring reliable operation. This reliability is crucial for maintaining the efficiency and performance of the equipment.

The materials used in custom coolant hoses are also selected based on the specific requirements of the application. This selection process ensures that the hoses can withstand the harsh conditions they may encounter, such as exposure to chemicals, high pressures, and bad temperatures. By using appropriate materials, custom coolant hoses provide predominant durability and resistance to wear and tear, further enhancing equipment performance.

Moreover, the flexibility of custom coolant hoses allows for better routing within the equipment. Proper routing is essential for efficient coolant flow and avoiding potential obstructions. Custom coolant hoses can be designed to navigate tight spaces and complex pathways, ensuring that the coolant reaches all necessary components without hindrance. This efficient routing helps maintain consistent cooling and prevents hotspots that could affect equipment performance.

Another important aspect of custom coolant hoses is their role in noise reduction. Equipment noise can be a significant issue in many industrial settings. Custom coolant hoses are designed to less vibrations and noise caused by the coolant flow. By reducing noise, these hoses contribute to a quieter and more comfortable working environment, which can enhance overall productivity.

Maintenance and replacement of custom coolant hoses are also more straightforward compared to standard hoses. Since custom coolant hoses are designed to fit specific equipment, they can be replaced more easily without extensive modifications. This ease of maintenance reduces downtime and ensures that the equipment can return to operation quickly.

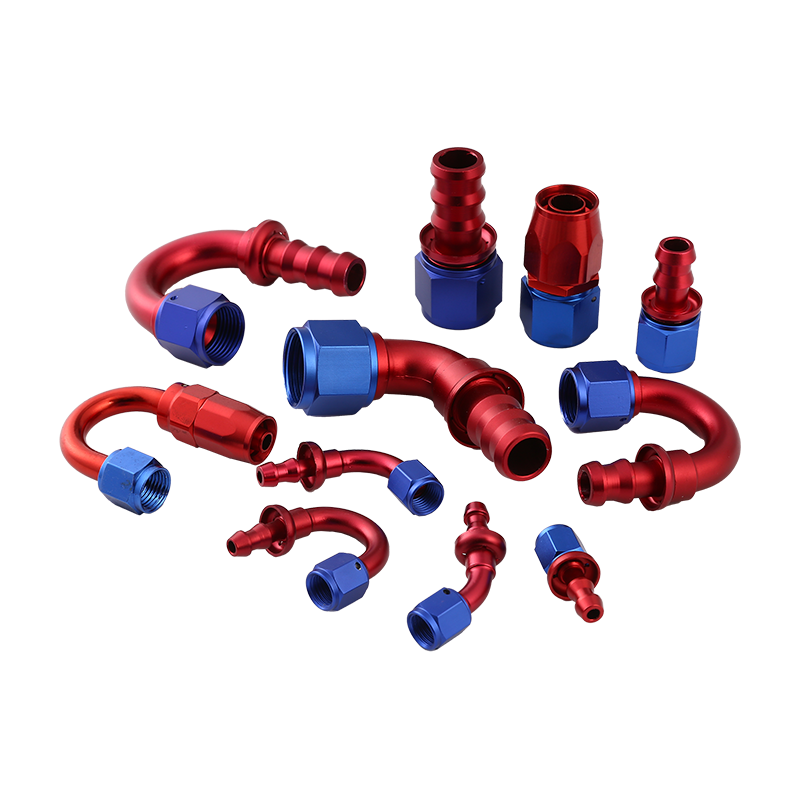

Furthermore, custom coolant hoses can be designed with specific connectors and fittings to match the equipment's requirements. These connectors ensure a secure and leak-free connection, further enhancing the reliability of the cooling system. By providing a tailored solution, custom coolant hoses contribute to the overall efficiency and performance of the equipment.

In conclusion, custom coolant hoses play a vital role in improving equipment performance by ensuring efficient coolant flow, preventing overheating, reducing the risk of leaks, and enhancing durability. Their tailored design and material selection provide a reliable and efficient solution for maintaining good operating conditions in various industrial applications. By investing in custom coolant hoses, businesses can enhance the performance, longevity, and reliability of their equipment, pilot to increased productivity and reduced maintenance costs.

English

English

Español

Español