How Secure Fastening Impacts Fuel Line Reliability in Modern Vehicles

When sourcing automotive components such as fuel line coolant hose and fuel line fastener, one aspect often underestimated is the impact of fastening quality on the overall reliability of the fuel system. At AlwayTec, we understand that the fuel line fastener is more than just a simple clip or clamp—its design, material durability, and ease of installation directly affect vehicle performance and maintenance costs.

Durability: The Foundation of Reliable Fastening

Durability is essential for fuel line fasteners, as they face constant exposure to vibrations, temperature fluctuations, chemicals, and moisture. Fasteners made from corrosion-resistant materials, such as stainless steel or specially treated alloys, offer longer service life compared to standard metals.

Additionally, the fastener’s ability to resist mechanical fatigue is critical. Repeated engine vibrations can cause inferior fasteners to crack or deform, eventually loosening the hose connection. Durable fasteners maintain a tight grip over time, preventing coolant or fuel leaks that could damage the engine or reduce efficiency.

At AlwayTec, our fasteners undergo rigorous material testing to ensure resistance to corrosion, temperature changes, and mechanical stress, providing stable and lasting performance in demanding environments.

Structural Types: Matching Application Needs

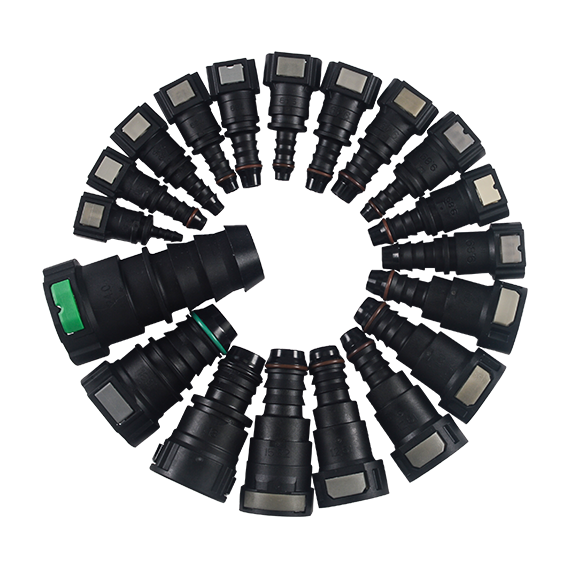

Fuel line fasteners come in various structural designs, each suited for specific applications:

Worm Gear Clamps: Adjustable and versatile, ideal for hoses with variable diameters. They provide a tight seal by tightening the screw mechanism.

Spring Clamps: Use spring tension to maintain pressure on the hose. They adapt well to temperature changes by expanding or contracting without losing grip.

Quick-Release Clamps: Designed for ease of assembly and disassembly, useful in situations requiring frequent maintenance.

Ear Clamps: Provide uniform pressure and are often used for permanent or semi-permanent connections.

Understanding which clamp type fits your assembly requirements is vital. For example, a spring clamp might be preferred in a cooling system with frequent temperature swings, while a worm gear clamp could be better for adjustable fittings.

Our product line covers multiple fastener types, allowing buyers to choose the ideal fit for their specific fuel line assemblies and operating conditions.

Installation Convenience: Saving Time and Costs

Fastener design also affects how easily and quickly they can be installed. Labor costs and assembly errors can be reduced significantly by choosing fasteners engineered for simple installation:

Tool Compatibility: Fasteners that require standard tools or offer tool-free options improve installation efficiency.

Ergonomic Features: Designs that allow easy grip and positioning reduce assembly time.

Reusability: Some fasteners are designed to be reused without losing clamping force, ideal for serviceable parts.

By prioritizing installation convenience, procurement managers can streamline production lines and minimize downtime during vehicle servicing.

At AlwayTec, we provide fasteners optimized for both automated assembly and manual installation, supporting diverse manufacturing environments.

Why Work With Us?

Our company’s focus on quality and customer needs means we offer fasteners that combine durability, suitable structural types, and ease of use. With over 150 customized fuel assemblies and continuous development, we tailor solutions that help you meet precise technical and operational requirements.

By partnering with us, you benefit from

Stable and tested material quality

A broad selection of fastener designs

Technical support for installation and customization

If you want to explore our full range of fasteners and fuel line coolant hoses, please reach out. We’re committed to supporting your success with quality products and responsive service.

English

English

Español

Español