Choosing the Right Fuel Line Connectors and Fasteners for Custom Assemblies

When assembling fuel line systems, selecting the right fuel line coolant hose, connectors, and fuel line fastener is critical, especially for custom or specialized applications. At AlwayTec, we provide over 150 customized fuel assemblies tailored to diverse client needs. To help procurement professionals make informed decisions, here we discuss important considerations when choosing connectors and fasteners for custom fuel line assemblies.

Understanding Your Assembly Requirements

Custom fuel line assemblies vary widely depending on vehicle design, engine type, and operating conditions. Before selecting connectors and fasteners, it is important to clearly define:

Fluid Type: Whether the line carries fuel, coolant, or both affects material compatibility and sealing requirements.

Pressure and Temperature: High-pressure or high-temperature environments demand connectors and fasteners with enhanced strength and durability.

Space Constraints: Limited installation space or complex routing may dictate specific connector shapes, sizes, or fastener styles.

Serviceability: Assemblies that require frequent maintenance or quick disassembly benefit from quick-connect fittings and tool-free fasteners.

Knowing these parameters guides you to select parts that fit well and perform reliably under specific conditions.

Matching Connectors to Hose Types

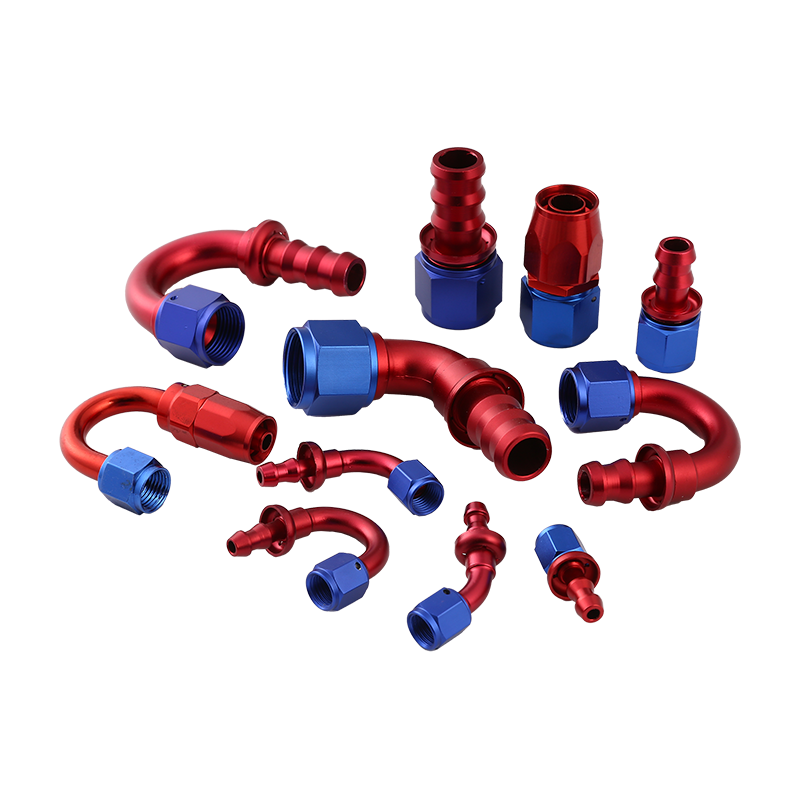

Fuel line connectors must be compatible with the fuel line coolant hose material and diameter to ensure leak-free operation and system integrity. Common connector types include quick-connect fittings, threaded fittings, and barbed connectors.

Quick-connect fittings facilitate faster assembly and reduce installation errors by eliminating the need for additional clamps or tools. However, they must be paired with hoses designed to accept these connectors securely to avoid accidental disconnection.

Threaded fittings offer a reliable and secure connection but may require more time and tools for assembly. Barbed connectors are typically used with flexible hoses and secured using clamps or fasteners.

At AlwayTec, our connectors are designed with precise tolerances and robust sealing features to minimize the risk of leaks or disconnections in custom assemblies.

Selecting Suitable Fuel Line Fasteners

Fasteners hold the hose-connector interface tightly, preventing leaks and disconnections. In custom assemblies, fastener selection depends on several factors:

Clamping Force: Fasteners must provide sufficient and even clamping force to prevent hose slippage under vibration, pressure changes, and thermal expansion.

Material: Corrosion-resistant materials such as stainless steel, plated alloys, or durable plastics extend service life in harsh environments.

Installation Method: Depending on the assembly process, tool-free clips or screw-type clamps may be preferred to balance speed and reliability.

Reusability: Some fasteners are designed for multiple uses, aiding maintenance and reducing replacement costs.

Our extensive fastener range supports various assembly needs, balancing strength, corrosion resistance, and ease of installation.

Benefits of Partnering with a Custom Assembly Supplier

Working with a supplier that offers both connectors and fasteners ensures compatibility, reduces procurement complexity, and streamlines communication. At AlwayTec, we collaborate closely with customers to:

Develop custom assemblies tailored precisely to vehicle models and operating conditions.

Conduct rigorous testing under real-world scenarios to validate product performance.

Provide ongoing technical support during design, production, and after-sales service.

This integrated approach leads to fuel line assemblies that meet strict safety and performance requirements while simplifying your supply chain.

Procurement Recommendations

To optimize sourcing of custom fuel pipe assemblies, we suggest the following:

Provide detailed specifications, including hose type, pressure and temperature ratings, environmental conditions, and installation constraints.

Request samples or prototypes for validation before committing to bulk orders.

Choose suppliers who offer customization options and are responsive to technical inquiries.

Verify compliance with relevant automotive and industry standards to ensure quality and safety.

If you have custom assembly projects or would like guidance on product selection, please contact us. We are eager to provide high-quality, tailored solutions to support your success.

English

English

Español

Español